Nema 17 (42mm) hollow shaft stepper motors

>> Short Descriptions

| Motor Type | Bipolar stepper |

| Step Angle | 1.8° |

| Voltage (V) | 2.6 / 3.3 / 2 / 2.5 |

| Current (A) | 1.5 / 1.5 / 2.5 / 2.5 |

| Resistance (Ohms) | 1.8 / 2.2 / 0.8 / 1 |

| Inductance (mH) | 2.6 / 4.6 / 1.8 / 2.8 |

| Lead Wires | 4 |

| Holding Torque (N.m) | 0.22 / 0.35 / 0.5 / 0.6 |

| Motor Length (mm) | 34 / 40 / 48 / 60 |

| Ambient Temperature | -20℃ ~ +50℃ |

| Temperature Rise | 80K Max. |

| Dielectric Strength | 1mA Max. @ 500V, 1KHz, 1Sec. |

| Insulation Resistance | 100MΩ Min. @500Vdc |

>> Certifications

>> Electrical Parameters

|

Motor Size |

Voltage/ Phase (V) |

Current/ Phase (A) |

Resistance/ Phase (Ω) |

Inductance/ Phase (mH) |

Number of Lead Wires |

Rotor Inertia (g.cm2) |

Holding Torque (N.m) |

Motor Length L (mm) |

|

42 |

2.6 |

1.5 |

1.8 |

2.6 |

4 |

35 |

0.22 |

34 |

|

42 |

3.3 |

1.5 |

2.2 |

4.6 |

4 |

55 |

0.35 |

40 |

|

42 |

2 |

2.5 |

0.8 |

1.8 |

4 |

70 |

0.5 |

48 |

|

42 |

2.5 |

2.5 |

1 |

2.8 |

4 |

105 |

0.6 |

60 |

>> General technical parameters

|

Radial clearance |

0.02mm Max (450g load) |

Insulation resistance |

100MΩ @500VDC |

|

Axial clearance |

0.08mm Max (450g load) |

Dielectric strength |

500VAC, 1mA, 1s@1KHZ |

|

Max radial load |

25N (20mm from flange surface) |

Insulation class |

Class B (80K) |

|

Max axial load |

10N |

Ambient temperature |

-20℃ ~ +50℃ |

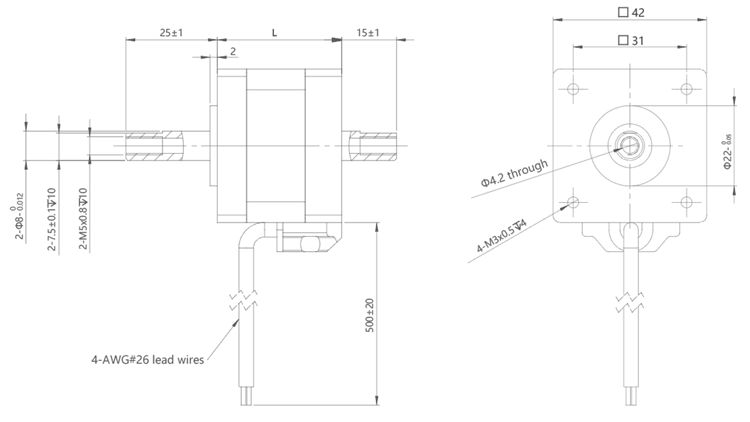

>> 42HK2XX-X-4B motor outline drawing

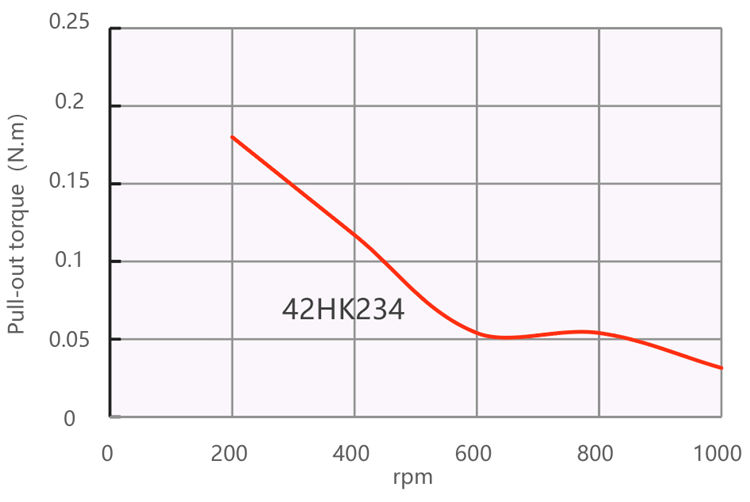

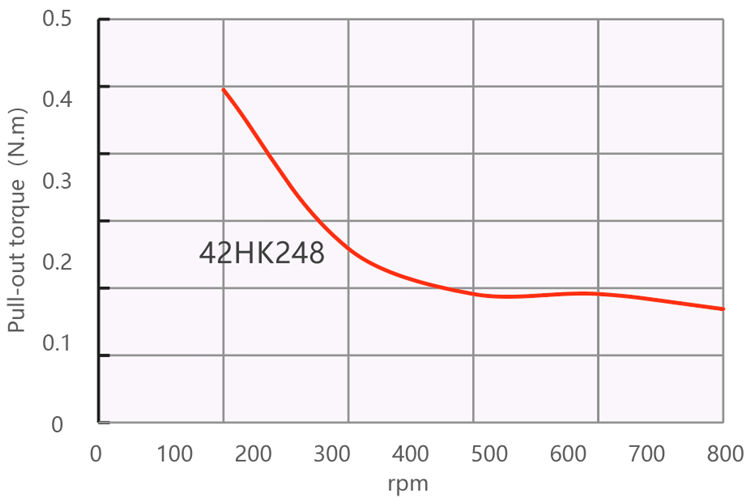

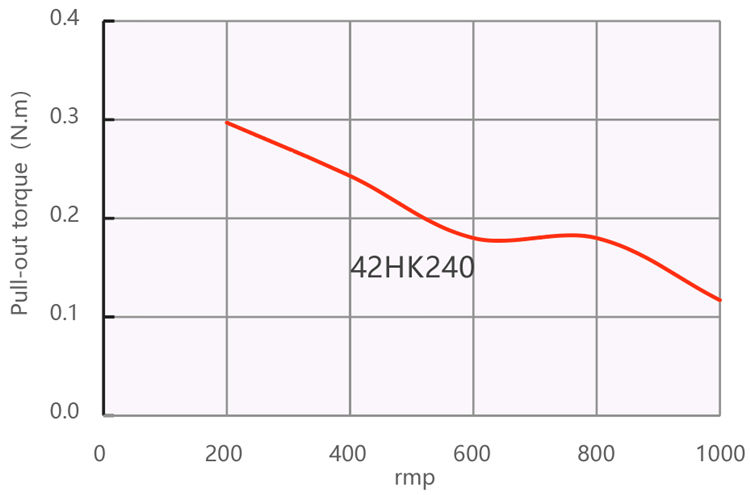

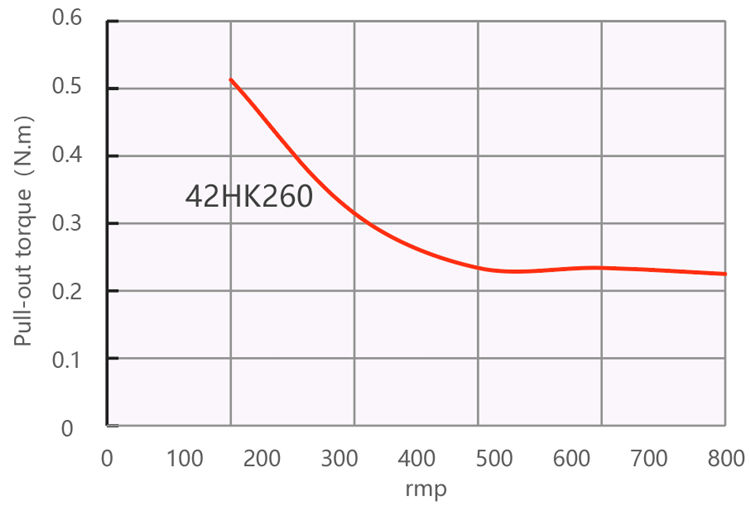

>> Torque-frequency curve

Test condition:

Chopper drive, no ramping, half micro-stepping, drive voltage 40V

>> About us

With the technology as the core, develop and produce high-quality products according to the diverse needs of the market. With this concept,the company will continue to develop products with high added values and continuously improve products,and will provide many customers with the best products and services!

Taking the core concept of "to be the Responsible". We will redound up on society for high quality products and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

Certainly, competitive price, suitable package and timely delivery will be assured as per customers' demands. We sincerely hope to build business relationship with you on the basis of mutual benefit and profit in the very near future. Warmly welcome to contact us and become our direct cooperators.

We have 8 CNC lathes, 1 CNC milling machine, 1 wire cutting machine, and some other machining devices. We are capable of machining most of the non-standard parts by ourselves in house to shorten the lead time of customized products, and to provide our customers with a good purchasing experience. Usually, the lead time of our lead screw motor products is within 1 week, and the lead time of ball screw is about 10 days.

Our products are 100% functional and safety tested before shipment to ensure that the products provided to customers are with high-quality.